Operational Efficiency & Progress Tracking using Drones

Overview

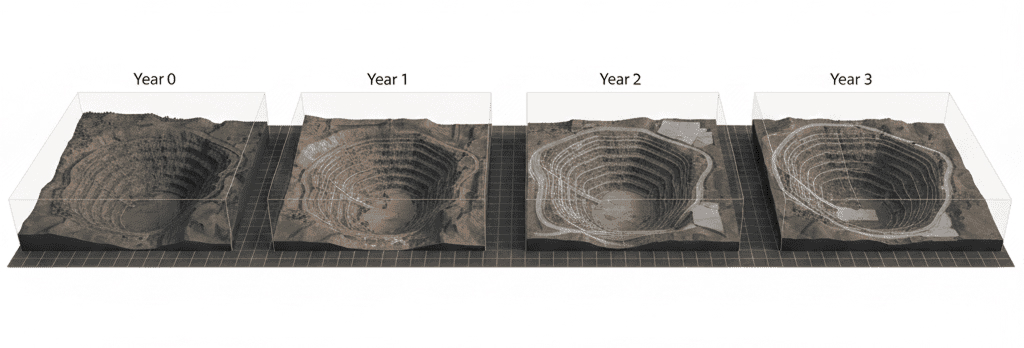

Drone-based operational monitoring enables mining operators to track daily excavation progress with high accuracy and minimal disruption. By capturing frequent aerial data, drones generate up-to-date maps and 3D models that can be compared against planned timelines and production targets. This provides clear visibility into material movement, bench advancement, and haul-road utilization. The resulting insights help identify operational bottlenecks, equipment underutilization, and deviations from planned schedules, enabling management teams to take timely corrective actions. Drone-enabled progress tracking enhances productivity, improves coordination across teams, and supports data-driven decision-making for optimized mine operations.

Process Flow

Reference Image

Relevant Outcomes / Deliverables

| Deliverable | Format | Usage |

|---|---|---|

| Progress Maps | GeoTIFF | Daily / weekly monitoring |

| Cut–Fill Analysis | DXF / SHP | Excavation tracking |

| Volume Change Report | CSV / PDF | Production assessment |

| Visual Progress Dashboard | Web / PDF | Management review |

Achievable Accuracy

| Parameter | Typical Accuracy | Depends On |

|---|---|---|

| Volume Change Accuracy | ±3–5% | Survey frequency, surface texture |

| Spatial Accuracy | ±3 cm | RTK/PPK and GCPs |

Key Advantages

- Near real-time visibility of mining progress

- Early identification of operational bottlenecks

- Improved schedule adherence and productivity

- Reduced dependence on manual reporting

Compatible Drone Platforms

- Multirotor UAVs for frequent, high-detail surveys

- Fixed-wing UAVs for large operational areas

Supported Sensors / Payloads

- RGB Cameras

- LiDAR Sensors (optional for complex terrain)

Industry Segments Benefited

- Mining Operations

- Quarry Management

- Project Planning Teams

- Production Managers

No sub drone applications found for this category.