Key Highlights

100%

Aerospace-Grade Structural Strength

90%

Reduction in UAV Airframe Weight

80%

Precision Manufacturing Accuracy

70%

Increased Endurance & Payload Efficiency

60%

Cost Reduction vs Imported Composite Parts

40%

Boost in Aerodynamic Performance

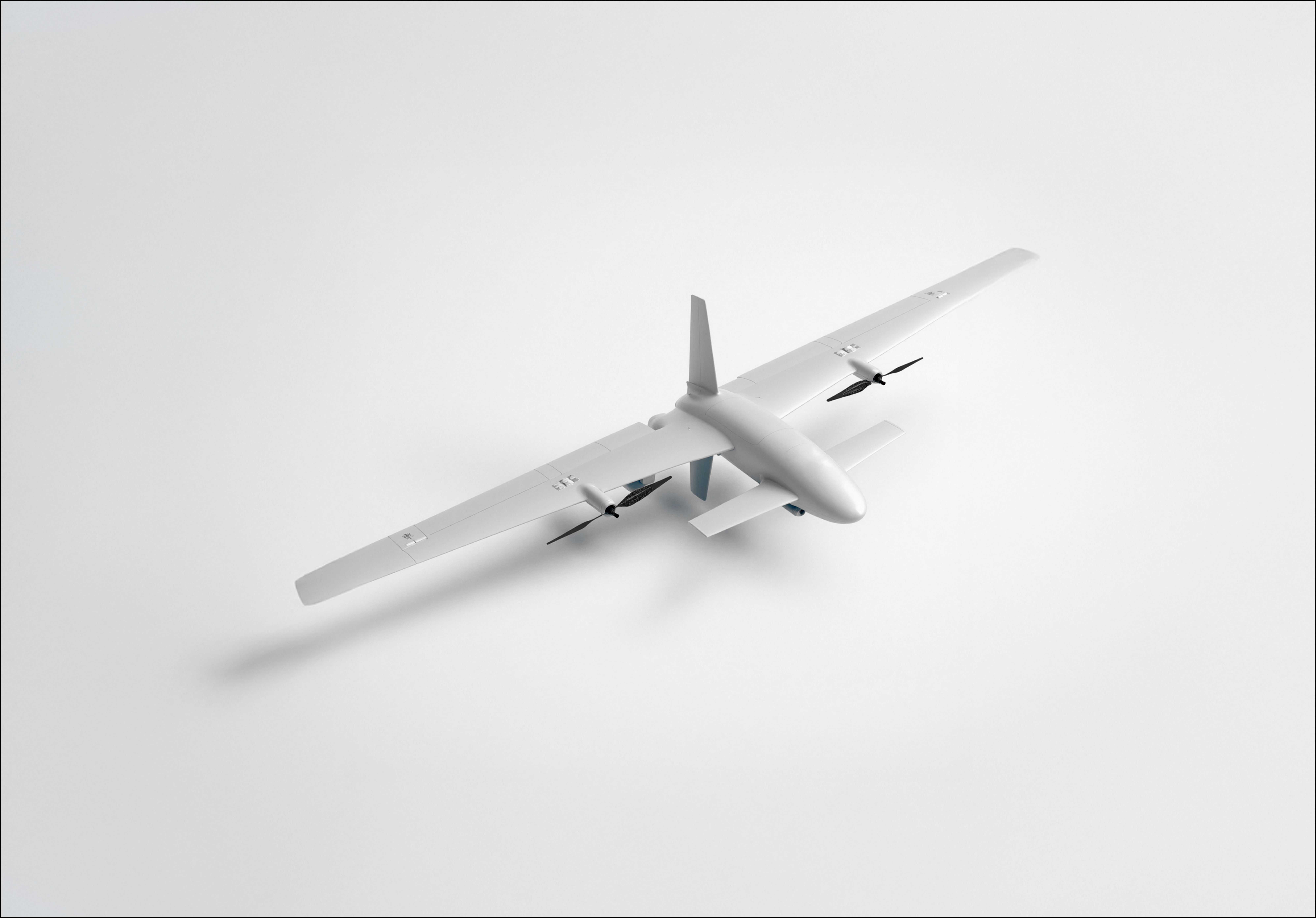

Strength in Lightness

RoboClave, the composite manufacturing division of the AKSI Group, is redefining aerospace materials through lightweight, high-strength, and sustainable composite solutions. Traditional metals can no longer meet the endurance and efficiency demands of modern UAVs and aerospace platforms. RoboClave bridges this gap by engineering carbon fiber, Kevlar, and hybrid composite structures that deliver the perfect balance between strength, durability, and aerodynamic efficiency.

Designed, developed, and produced in India, RoboClave’s composites form the structural backbone of AKSI’s next-generation UAVs — from airframes and landing gears to propeller blades and payload housings. With cutting-edge facilities and a deep commitment to innovation, RoboClave ensures that every gram of material contributes to greater endurance, payload capacity, and sustainability, driving the future of aerospace and beyond.

Target Industries & Applications

RoboClave composites serve as critical structural enablers across multiple high-performance industries:

Unmanned Aerial Vehicles (UAVs)

Airframes, propellers, and landing structures.

Aerospace

Lightweight fuselage panels and aerodynamic components.

Defense

Ballistic-grade Kevlar composites for protective systems.

Automotive

Lightweight hybrid panels for electric and performance vehicles

Renewable Energy

Structural elements for wind turbine blades.

By enabling superior strength-to-weight performance, RoboClave ensures that every product—from drones to aircraft—flies farther, stronger, and more efficiently.

Unique Features

High strength-to-weight ratio

For improved endurance and payload performance

Durable & Weather-Resistant

Composites suitable for extreme environments.

Precision Manufacturing

Using autoclave curing, CNC machining, and advanced molding systems.

Aerodynamic Optimization

For improved flight stability and efficiency.

Aerospace-Grade Clean-Room Production

Ensuring consistent quality

Sustainability Built-In

Using recyclable and long-life composite materials.

How RoboClave Stands Distinctly

RoboClave’s distinction lies in its vertically integrated composite ecosystem within AKSI’s manufacturing framework. Unlike conventional component fabricators, RoboClave manages the entire process—from fiber selection and resin formulation to molding and curing—under one roof. This allows for faster prototyping, higher precision, and lower costs compared to imported alternatives.

With advanced R&D focused on nano-composites and bio-composites, RoboClave is pioneering materials that are stronger, lighter, and more recyclable, supporting India’s vision of sustainable aerospace manufacturing. Its products not only power AKSI drones like Skywing90, KhetPilot, and Slatup, but also serve defense, automotive, and renewable energy sectors worldwide — establishing RoboClave as a global leader in composite innovation.

| Product Category | Description |

|---|---|

| Aerospace-Grade Carbon Composites | Lightweight airframes, propeller blades, and structural panels for UAVs. |

| Kevlar & Hybrid Composites | High-impact materials for defense and automotive applications. |

| Custom Composite Solutions | Tailor-made components for aerospace, EV, and renewable energy sectors. |