Drone-based infrastructure maintenance and inspection dramatically improves the way bridges, roadways, rail corridors, and tunnels are assessed for structural health. Using high-resolution RGB, zoom, thermal, and LiDAR sensors, drones capture detailed visuals of cracks, corrosion, deformation, and surface degradation—without requiring traffic blocks, scaffolding, or physical entry into hazardous zones. For bridges and roadways, drones enable close-range imaging of joints, beams, decks, and hard-to-reach undersides, ensuring early detection of structural issues. In railway and tunnel environments, drones provide safe navigation through confined or GPS-denied areas, capturing critical data on track alignment, tunnel lining integrity, water ingress, and clearance deviations. This non-contact inspection method enhances accuracy, reduces risk to workers, and speeds up maintenance cycles, while generating digital records for long-term asset management. Together, these drone-enabled capabilities bring unmatched efficiency, safety, and precision to modern infrastructure monitoring.

Railway and Tunnel Inspections

Railway Track and Tunnel Inspection using Drones

Overview

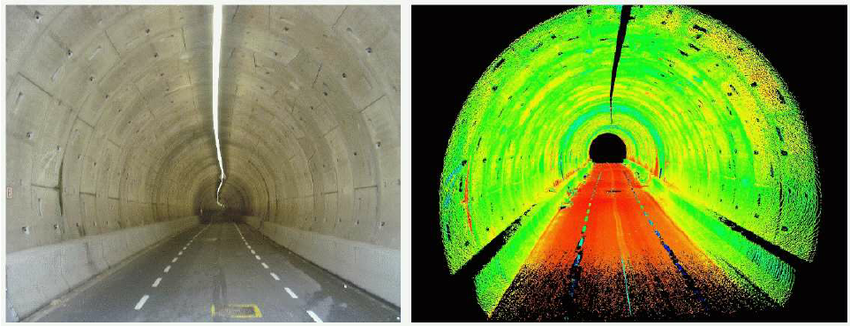

Railway and tunnel inspections with drones provide a safe, efficient, and non-intrusive way to monitor infrastructure health in challenging or confined environments. Drones equipped with high-lumen lighting, LiDAR, and thermal sensors capture detailed imagery of tracks, walls, and tunnel linings to detect cracks, leaks, or misalignments. This approach eliminates the need for human entry in hazardous zones and ensures continuous, accurate monitoring of railway assets.

Process Flow

Reference Image

Relevant Outcomes / Deliverables

| Deliverable | Format | Usage |

|---|---|---|

| Tunnel Scan / 3D Model | OBJ / PLY / LAS | Structural analysis |

| Defect Report | PDF / CSV | Maintenance scheduling |

| Alignment Map | GeoTIFF / SHP | Track alignment validation |

| Visual Record | MP4 / JPG | Documentation for audits |

Achievable Accuracy

| Parameter | Typical Accuracy | Depends On |

|---|---|---|

| Crack Detection | ~1 mm | Lighting & camera resolution |

| Positional Accuracy | ±3–5 cm | GNSS / IMU quality, tunnel GPS loss compensation |

Key Advantages

- Enables inspection in confined or GPS-denied environments

- Reduces inspection time by up to 70%

- Eliminates human risk in tunnels and underpasses

- Generates precise 3D models for clearance and safety checks

Compatible Drone Platforms

- Collision-tolerant drones (Micro-Ranger)

- Compact multirotors with obstacle avoidance

Supported Sensors / Payloads

- RGB + Thermal Cameras

- LiDAR or Depth Sensors

- High-Intensity LED Lighting Systems

Industry Segments Benefited

- Indian Railways

- Metro Rail

- Tunnel Engineering Firms

- Infrastructure Consultants

- Safety Auditors

Bridge and Roadway Inspections

Bridge and Roadway Structural Inspections using Drones

Overview

Drone-based bridge and roadway inspections revolutionize infrastructure maintenance by providing a non-contact, high-resolution assessment of structural health. Drones equipped with optical, thermal, or LiDAR sensors capture detailed visuals of cracks, corrosion, joint misalignment, or surface degradation — all without traffic disruption. This technology ensures safety, reduces downtime, and enables proactive maintenance planning through precise visual documentation and analytics.

Process Flow

Reference Image

Relevant Outcomes / Deliverables

| Deliverable | Format | Usage |

|---|---|---|

| Visual Inspection Report | PDF / Web Dashboard | Maintenance planning |

| Thermal Map | JPG / GeoTIFF | Detect material fatigue & water ingress |

| 3D Model / Point Cloud | OBJ / LAS | Structural modeling & deformation study |

| Video Footage | MP4 | Documentation & monitoring |

Achievable Accuracy

| Parameter | Typical Accuracy | Depends On |

|---|---|---|

| Crack Detection | up to 1–2 mm | Camera resolution, distance |

| Dimensional Accuracy | ±2–5 cm | Sensor calibration, flight stability |

Key Advantages

- Non-contact, safe inspection of inaccessible areas

- No traffic disruption or scaffolding required

- Detects micro-cracks and corrosion early

- Enables digital archiving and predictive maintenance

Compatible Drone Platforms

- Multirotor (Skywing90) for close-up inspection

- Tethered drones for long-duration bridge surveys

Supported Sensors / Payloads

- RGB / Zoom Cameras (45× optical zoom)

- Thermal / IR Sensors

- LiDAR (optional for structural 3D modeling)

Industry Segments Benefited

- Highway Authorities

- PWD

- Smart City Agencies

- Infrastructure Consultants

- Bridge Maintenance Firms