Equipment & Infrastructure Inspection using Drones

Overview

Drone-based equipment and infrastructure inspection enables safe, rapid, and detailed assessment of mining machinery and processing facilities. High-resolution visual and thermal imagery allows operators to inspect conveyors, crushers, transfer points, silos, and plant structures without halting operations or exposing personnel to hazardous environments. Early detection of wear, overheating, misalignment, or structural damage helps prevent unplanned shutdowns, reduces maintenance costs, and extends equipment life. By integrating drone data into maintenance planning, mining operators can transition from reactive repairs to proactive, condition-based maintenance strategies.

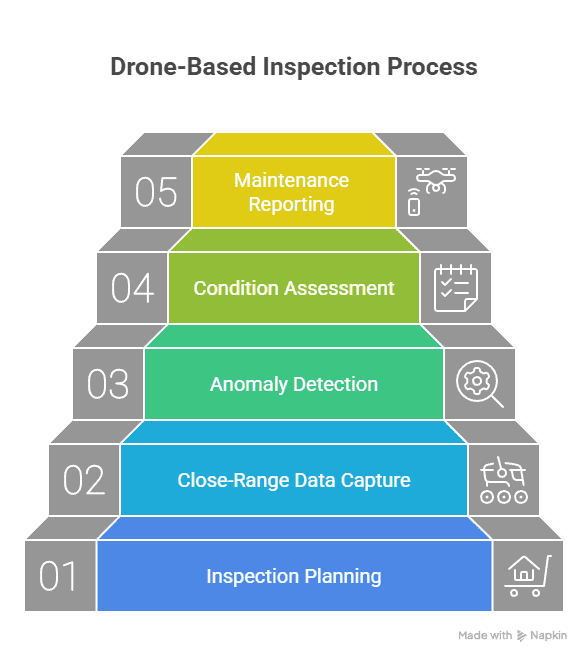

Process Flow

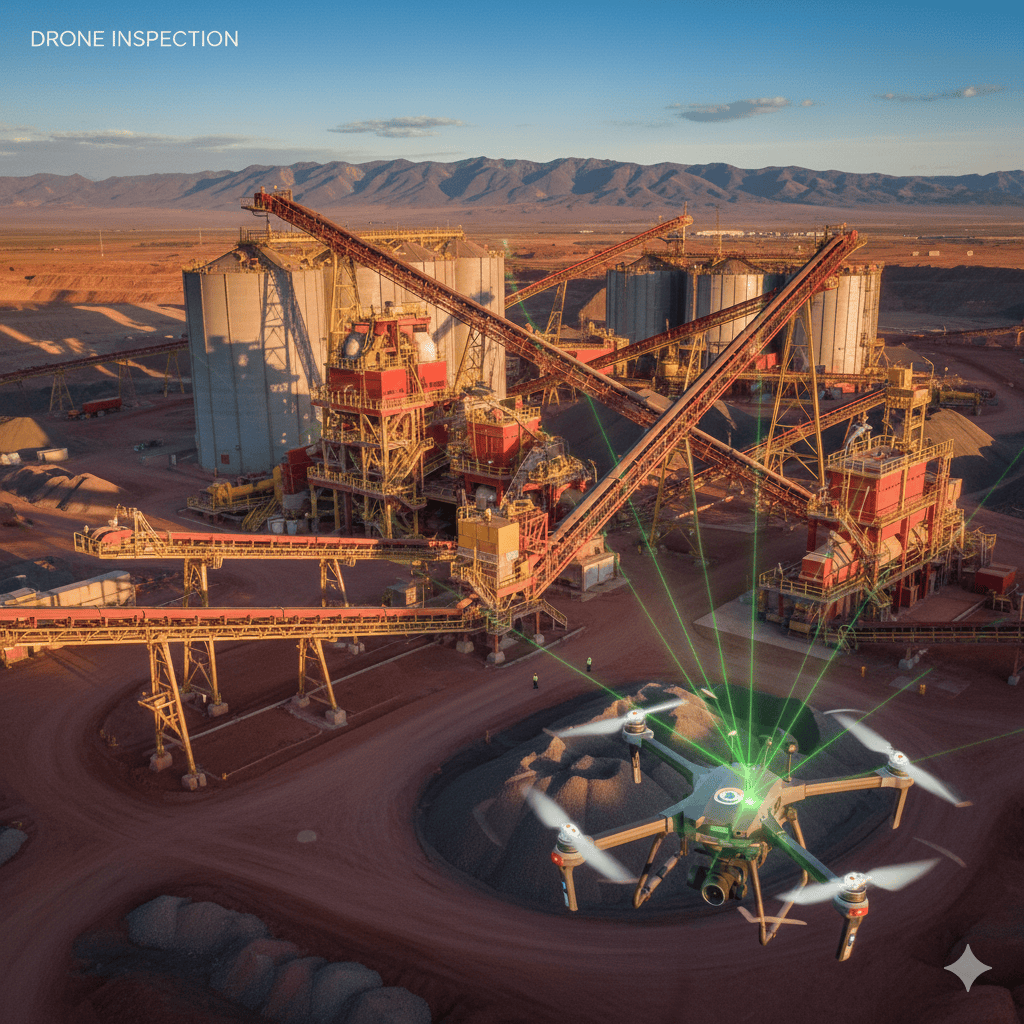

Reference Image

Relevant Outcomes / Deliverables

| Deliverable | Format | Usage |

|---|---|---|

| Visual Inspection Report | Maintenance planning | |

| Thermal Anomaly Map | JPG / PDF | Overheating detection |

| High-Resolution Imagery | JPG / TIFF | Damage documentation |

| Maintenance Priority List | CSV | Preventive maintenance |

Achievable Accuracy

| Parameter | Typical Accuracy | Depends On |

|---|---|---|

| Defect Detection | Sub-millimeter (visual) | Camera resolution & inspection distance |

| Thermal Accuracy | ±2 °C | Sensor calibration |

Key Advantages

- Non-contact inspection of active equipment

- Early fault detection before catastrophic failure

- Reduced downtime and maintenance costs

- Enhanced worker safety in hazardous zones

Compatible Drone Platforms

- Multirotor UAVs with obstacle avoidance

- Compact drones for confined plant environments

Supported Sensors / Payloads

- RGB / Zoom Cameras

- Thermal Cameras

Industry Segments Benefited

- Mining Operations

- Processing Plants

- Maintenance Teams

- Industrial Facilities

No sub drone applications found for this category.