Drone Safety Inspections for Hazard & Risk Detection in Mining Sites

Overview

Safety is paramount in mining operations. Drones enable close inspection of high walls, benches, pits, and tailings without exposing personnel to risk. Thermal, visual, and LiDAR payloads detect ground instabilities, erosion, and structural defects before they escalate into accidents. Regular aerial surveillance helps maintain regulatory compliance and minimize downtime due to safety incidents.

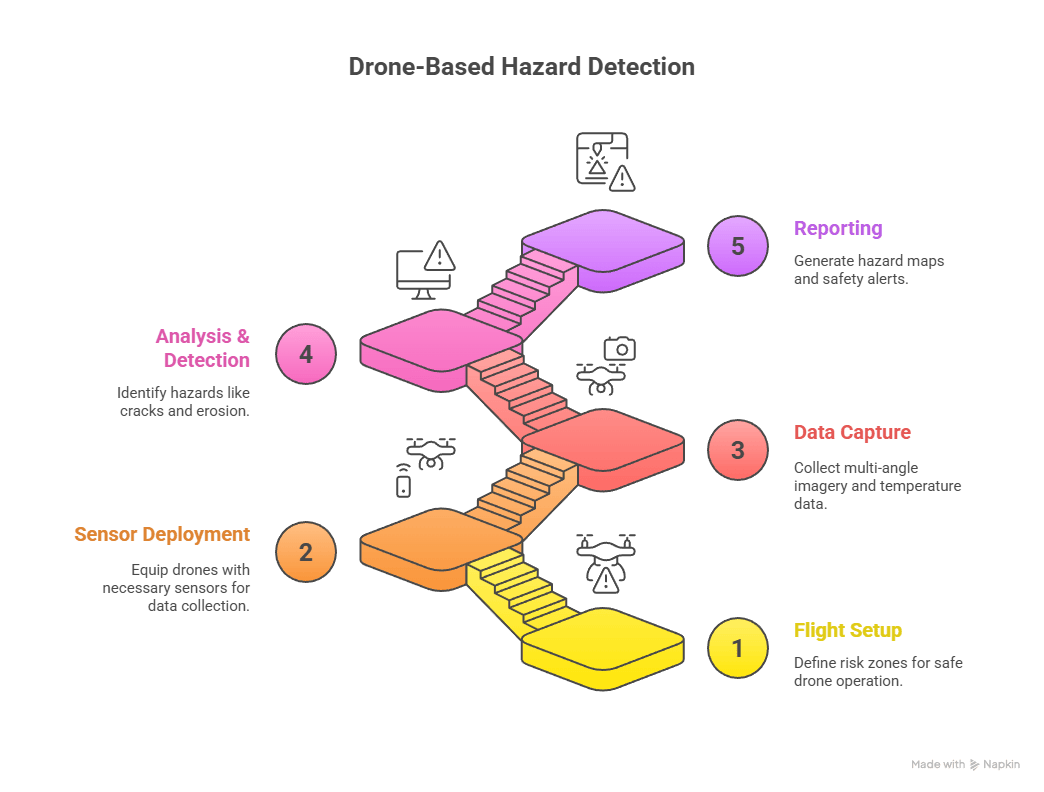

Process Flow

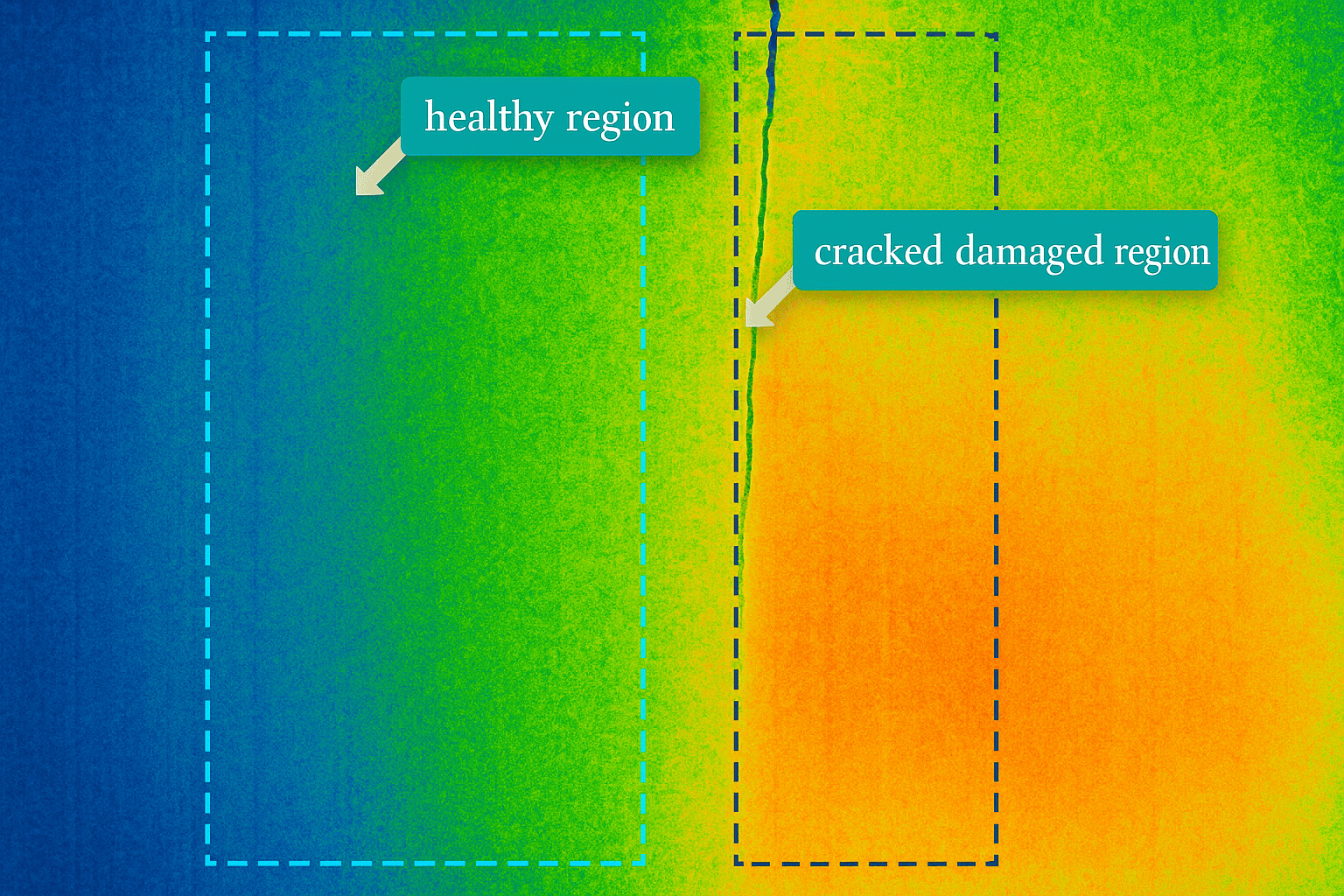

Reference Image

Relevant Outcomes / Deliverables

| Deliverable | Format | Usage |

|---|---|---|

| Hazard Detection Map | GeoTIFF | Safety risk visualization |

| Thermal Report | PDF / JPG | Heat and stability assessment |

| 3D Surface Model | LAS / OBJ | Erosion monitoring |

| Inspection Video | MP4 | Evidence and training use |

Achievable Accuracy

| Parameter | Typical Accuracy | Depends On |

|---|---|---|

| Crack Detection | 1–3 mm | Camera resolution |

| Temperature Accuracy | ±2 °C | Thermal calibration |

Key Advantages

- Safe inspection of hard-to-reach zones

- Early warning of geotechnical risks

- Thermal and visual correlation for root-cause analysis

- Reduces workplace accidents and downtime

Compatible Drone Platforms

- Multirotor (DJI M350 RTK, Mavic 3T Thermal)

- Collision-tolerant drones for confined spaces

Supported Sensors / Payloads

- RGB

- Thermal

- LiDAR

- Multispectral (optional)

Industry Segments Benefited

- Mining

- Quarry Safety

- Environmental Agencies

- Geotechnical Firms

No sub drone applications found for this category.